Building a vehicle engine is a complex and intricate process that intrigues mechanics and car fans all over the world.

- DIY Spring Tune Up with GM Parts – Part 2: Spark Plugs

- Tips to Tackle Your First Big Car Repair From A Fellow Rookie

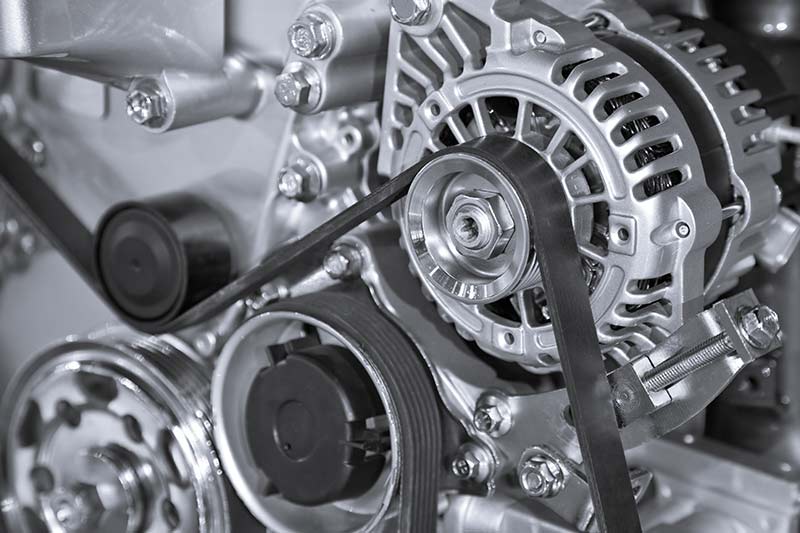

Mechanics can fix or replace your engine, but it’s still helpful to know the basics of engine components and how it’s made. This will help you to understand engine parts, which is helpful when visiting an auto repair shop.

We’ll discuss the core components of a car engine for beginners, and then move on to how a car manufacturer assembles an engine versus how a car enthusiast might.

Core components of the engine explained

Before we can discuss how an engine is built, we need to know the core components. Though cars and their internal components are manufactured differently (to separate themselves from other car manufacturers), the basics of what goes into an engine is the same across the board. There are a few important parts and processes that every car owner should know.

One of the most important car parts is the cylinder, the core of a vehicle engine. A bank of four, six or eight cylinders is found in modern cars — the more pistons you have, the more power. They can be arranged in different ways. Flat engines pump horizontally. Inline engines pump vertically. V-engines are formed in the shape of a V. Pistons within the cylinder pump gas to the crankshaft and power the car.

Using fuel and air, the engine creates a contained explosion (combustion) to power the car. Valves intake air and fuel and expel exhaust, sealing the combustion chamber when the car is in use. The spark plug is what ignites the fuel and air solution to cause combustion.

How a car manufacturer assembles an engine

Unless you’re looking at a supercar with a limited run, car manufacturers build engines on a mass assembly line. This means the parts are mass-produced, and readily available. The engine goes through molding and casting, machining and then inspection.

The process starts with the creation of actual parts. Most modern engines and parts are made with a lightweight aluminum alloy. It’s more expensive, but it’s lighter, and tends to last longer than the old iron engines. The alloy is poured into molds and is left for hours to solidify.

Finished parts are machined together, and finally, the finished engine is inspected. Actual assembly of the car is usually done by technicians in stations that perform different tasks. During assembly, the vehicle frame is attached before the engine and transmission line.

Tips for building your own engine

Believe it or not, some automobile experts build their own engines, often for performance cars or specialized vehicles. Building your own car engine is demanding but rewarding. Though the process is similar to what is done by auto makers, you may not have access to top-of-the-line tools or robotics.

Building your engine involves putting every component together with care and great precision. The process can be difficult and monotonous, taking several days to complete. However, it’s a challenge that budding mechanics and experienced car buffs alike will enjoy.

Leave a Reply